Welcome to Shandong Xinghan Aluminum Industry Group Co., Ltd.

Tel : +8615562508601 E-mail : cnxh005@xhsteelgroup.com

ABOUT US

SHANDONG XINGHAN ALUMINUM INDUSTRY GROUP CO., LTD.

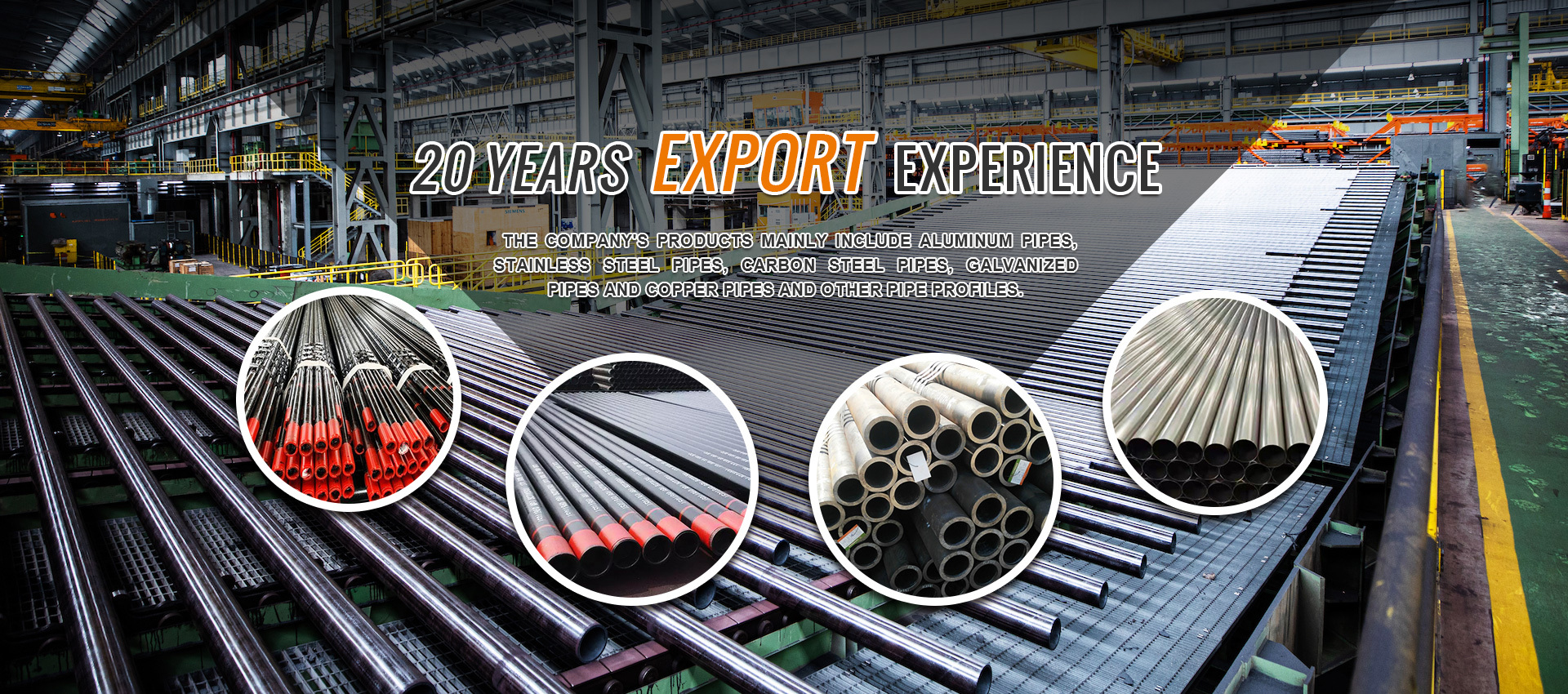

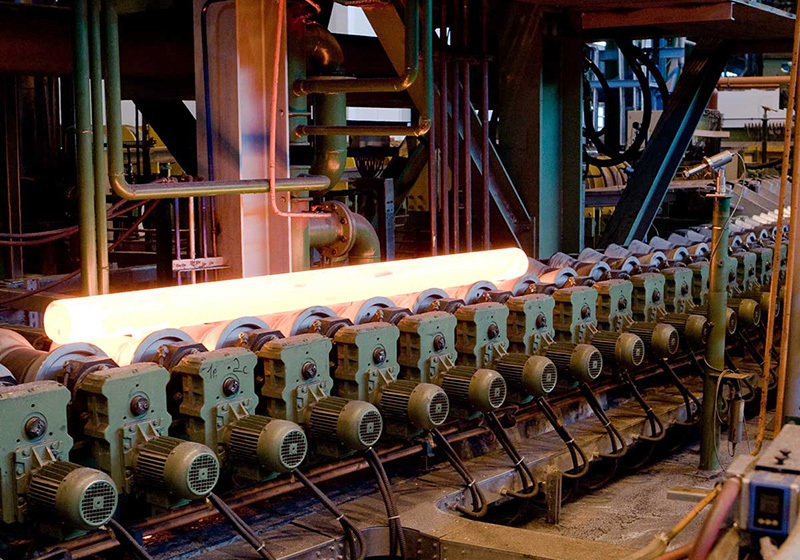

Shandong Xinghan Aluminum Industry Group Co., Ltd. was established in March 2010. It is a comprehensive large-scale enterprise integrating product production, warehousing, distribution and foreign trade sales. The company has main production lines such as pickling, cold rolling, hot-dip galvanizing, hot-dip galvanizing, thick plate galvanizing, and color coating, forming an annual output of 1 million tons of pickling coils, 1 million tons of cold-rolled steel sheets, and 900,000 tons of hot-dip steel sheets.

Founded

Employee

Floor Area

Exporting Country

PRODUCT CENTER

The products currently have Exported to more than 100 countries and regions such as Africa, the European Union, South America, Southeast Asia, and Central Asia.

TECHNOLOGICAL INNOVATION

The products currently have Exported to more than 100 countries and regions such as Africa, the European Union, South America, Southeast Asia, and Central Asia.

NEWS CENTER

The products currently have Exported to more than 100 countries and regions such as Africa, the European Union, South America, Southeast Asia, and Central Asia.

Temperature requirements for submerged arc welded straight seam steel pipes

The welding process used for submerged arc welded straight seam steel pipe is submerged arc welding technology, which adopts filler welding and particle protection flux submerged arc. The diameter of production can reach 1500mm. LSAW is the English abbreviation of submerged arc welded straight seam steel pipe. The production process of submerged arc welded straight seam steel pipe includes JCOE forming technology and coil forming submerged arc welding technology. When the diameter is large, two steel plates may be used for rolling, which will form the phenomenon of double welds.

Reducing misjudgment of high-pressure boiler pipe eddy current testing

Reducing high-pressure boiler pipe eddy current testing misjudgment several key factors: (1) Coil eddy current testing and inspection center roller consistency in relation to the accuracy inspection rate high pressure boiler tube inspection system of the entire product, the coil center alignment requirements than the sample through holes circumferentially poor sensitivity ≤2dB, signal to noise ratio ≥ 8dB.

What are the advantages of argon arc welding

Argon reduces the burning loss of alloy elements and obtains denseand high-quality welded joints; The protection can isolate the adverse effects of oxygen, nitrogen and hydrogen in the air on arcand molten pool.

The most practical steel pipe welding technology

Submerged arc welding technology is ideal for important applications such as pipelines, pressure vessels and tanks, rail manufacturing and large buildings. There are the simplest form of monofilament, double-filament structure, tandem double-filament structure, and multi-filament structure.

GET A FREE QUOTE